As an important carrier of modern information dissemination and visual art, the performance and stability of LED display screens are directly related to the display effect and application experience. As the basic unit of the entire system, the design and material selection of the LED display box are crucial. Today, I will explain how LED display screen enclosures can be classified and analyzed from several dimensions, including structural type, material composition, protection level, and installation method.

Structure type

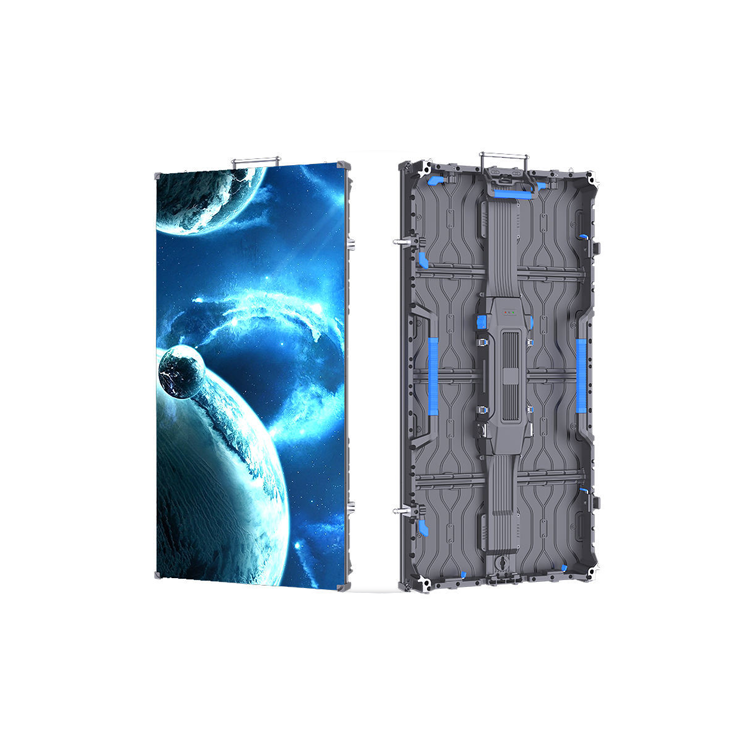

Standard enclosure: This is the most common type of LED display enclosure, typically designed with modularity for quick installation, disassembly, and maintenance. The standard box size is uniform, such as common specifications of 500mm × 500mm, 600mm × 600mm, etc., which can be flexibly spliced into display screens of any size and shape.

Front maintenance box: In response to the problem of leaving a large space for traditional rear maintenance methods, front maintenance boxes have emerged. This type of box is designed with a special door opening or sliding cover structure, allowing maintenance personnel to perform maintenance from the front without dismantling the entire screen, greatly improving maintenance efficiency and convenience.

Ultra thin case: With the advancement of technology, ultra thin cases have gradually become the new favorite of the market. They achieve a significant reduction in weight and thickness while ensuring strength through the use of lighter materials such as aluminum alloy and more precise manufacturing processes, making them particularly suitable for scenarios with strict requirements for installation space.

Material composition

The LED display box is usually composed of an outer shell, internal structural components, and a heat dissipation system. The shell is mostly made of high-strength aluminum alloy or cold-rolled steel plate, which has been sprayed or oxidized to have good corrosion resistance and aesthetics. The internal structural components are used to support the LED light board and circuit board, ensuring the stability of the overall structure. The cooling system effectively discharges the heat generated by LED operation through reasonable air duct design or components such as heat sinks and fans, ensuring the stable operation of the screen.

Protection level

The LED display box also needs to have a certain level of protection to prevent external factors such as dust and water mist from entering, which can affect the display effect and device life. Common protection levels include IP65, IP66, etc. IP65 means it can completely prevent dust from entering and withstand water spray from any direction without causing damage; IP66 goes a step further, indicating that it can withstand stronger water jets.

Installation method

According to different application scenarios, there are various installation methods for LED display box bodies, including wall mounted, suspended, column mounted, embedded, etc. Each installation method has its specific applicable scenarios and installation requirements, and choosing the appropriate installation method is crucial to ensuring the safety and stability of the display screen.

In summary, as the core component of the display system, the design and selection of the structure type, material composition, protection level, and installation method of the LED display box directly determine the performance and service life of the display screen. With the continuous advancement of technology and changes in market demand, the design of LED display box bodies will continue to innovate, bringing more exciting visual feasts to more fields.