Judging the quality of LED display screen materials can be comprehensively evaluated from multiple key dimensions. The following are detailed reference methods and points to note:

1. Appearance quality inspection

Surface treatment: The material surface should be smooth without obvious scratches, bubbles, deformations, or color differences, and the coating should be uniform and firm.

Color consistency: The colors of different batches or the same batch of materials should be consistent to avoid uneven color display on the screen.

Quality of plastic parts: The plastic shell or bracket should be free of cracks, burrs, and have good strength and toughness.

2. Material performance indicators

Weather resistance

The material should have good UV resistance, waterproof and moisture-proof ability, and be suitable for long-term outdoor use without yellowing or powdering.

Temperature resistance

It should remain stable in high or low temperature environments, without deformation or cracking.

Flame retardancy

Especially for materials used for circuit boards and connectors, they should comply with national or industry flame retardant standards (such as UL94-V0 grade).

Thermal conductivity

LED screens generate significant heat, and the back panel and thermal conductive material should have good thermal conductivity to facilitate heat dissipation and ensure display performance and lifespan.

3. Quality of electronic components

LED bead quality

Check the consistency of light color, brightness uniformity, and lifespan. High quality LED beads have stable brightness, bright colors, and a lifespan of tens of thousands of hours.

Driver IC and circuit board

PCB boards should be made of high temperature resistant FR4 or higher specification materials, with fine circuit soldering processes and no virtual soldering or solder leakage.

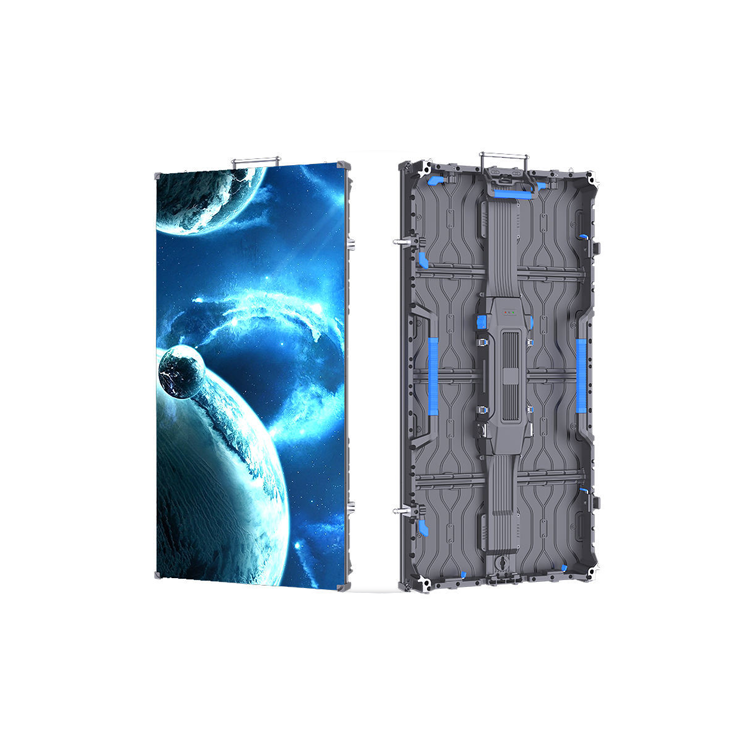

4. Physical and mechanical properties

Module stability

The module structure is compact, with good splicing flatness and no obvious gaps, ensuring seamless and aesthetically pleasing overall display.

Materials of connectors and installation components

Corrosion resistant and high-strength metal materials should be selected to avoid loosening or oxidation during long-term use.

5. Functional testing

Brightness and color testing

Use professional testing instruments to measure brightness uniformity and color reproduction to determine if they meet the design specifications.

Protection level test

If the IP rating is dustproof or waterproof, outdoor LED displays must meet IP65 or higher standards.

Durability testing

Simulate high and low temperature alternation, salt spray corrosion and other environments to test the stability of materials and overall structures.

6. Brand and Certification

Supplier Qualification

Choose reputable and certified suppliers to check if the materials have relevant certifications such as ISO9001, RoHS, CE, etc.

Material Testing Report

Require suppliers to provide detailed material testing and performance reports to ensure compliance with industry standards.

To judge the quality of LED display screen materials, it is necessary to start from multiple aspects such as appearance, physical properties, electronic components, functional testing, and supply chain qualifications, and conduct a comprehensive evaluation based on actual application environment and technical indicators. It is recommended to cooperate with professional testing instruments and laboratory testing to ensure that the selected materials can meet long-term stable and high-definition display requirements.